† Corresponding author. E-mail:

Project supported by the Nation Natural Science Foundation of China (Grant Nos. 11347219 and 11404147), the Natural Science Foundation of Jiangsu Province, China (Grant No. BK20140519), the Training Project of Young Backbone Teacher of Jiangsu University, the Advanced Talents of Jiangsu University, China (Grant No. 11JDG118), the Practice Innovation Training Program Projects for Industrial Center of Jiangsu University, China, and the State Key Laboratory of Acoustics, Chinese Academy of Sciences (Grant No. SKLOA201308).

The mechanical properties of graphene sheets with various grain boundaries are studied by molecular dynamics method at finite temperatures. The finite temperature reduces the ultimate strengths of the graphenes with different types of grain boundaries. More interestingly, at high temperatures, the ultimate strengths of the graphene with the zigzag-orientation grain boundaries at low tilt angles exhibit different behaviors from those at lower temperatures, which is determined by inner initial stress in grain boundaries. The results indicate that the finite temperature, especially the high one, has a significant effect on the ultimate strength of graphene with grain boundaries, which gives a more in-depth understanding of their mechanical properties and could be useful for potential graphene applications.

Graphene is a kind of nano-material, which was first produced in 2004. As is well known, two-dimensional (2D) pristine graphene has a high in-plane mechanical strength due to its strong sp2 C–C covalent bonds. This excellent mechanical property leads to its extensive applications in the mechanical and mechanical-electronic field.[1–5] However, synthesized large-area graphene inevitably contains the grain boundaries (GBs), which play an important role in the stability of 2D graphene crystalline structure. Studying the GB effects on the graphene physical properties is one of fundamental interest. For example, some GBs in graphene have perfect electron transport properties,[6,7] and heat rectification at the asymmetric grain boundaries in graphene is predicted theoretically.[8]

The tilt grain boundaries also affect the graphene mechanical strength. As is well known, the stretching limit of a material depends not only on its intrinsic strength of the chemical bonds between two atoms,[9] but also on the defects in it, such as the tilt grain boundaries. In 2010, Grantab et al.[10] showed by the molecular dynamics (MD) simulation method that when the tilt GB density in graphene increases, its stretching limit also increases, violating the conventional consideration. This anomalous mechanical phenomenon arouses the great interest of a vast number of researchers working in the material science and condensed matter physics. Two years later, another research team supplemented that the tilt GB distribution in graphene also affects the material stretching limit,[11] indicating that the stretching limit could increase or decrease, depending on the tilt angle of the armchair-oriented tilt GB. Following their work, many kinds of GBs, such as the zigzag-armchair-oriented ones with any tilt angle have been constructed in order to investigate the GB role in the stability of 2D graphene sheets.[12–21] In particular, Zhang et al. studied graphene sheets with sinuous grain boundaries which showed improved mechanical behavior.[22] The other 2D materials with grain boundaries have also been studied, e.g., metal dichalcogenides MX2 (M = Mo, W; X = S, Se) with grain boundaries.[23] Besides this, shear deformation on the GBs was also investigated theoretically.[24] All of these studies predicted that when the graphene sheet with the GBs was stretched to a limit length, the stress was mainly loaded on the heptagon rings. As a result, the bonds lying on the heptagon usually break first, then lead to a crack, which was immediately proved by the following work.[25] So in Ref. [21], the authors established a quasi-static strain model based on the bond breaking mechanism mentioned above to predict the final stretching failure of graphene sheet with grain boundary. However, all of these studies were carried out at room or low temperatures.

The temperature effects, especially the high-temperature effects, on elongation of graphene sheets with the GBs have not been discussed in detail, which cannot be ignored in practical applications as a real physical condition. Graphene must have intrinsic ripples to maintain its quasi 2D structure, while the temperature could affect the ripples in monolayer and bi-layer graphene.[26] The polycrystalline graphenes are not flat due to the existence of GBs,[11] which could also be affected by temperature. So in this work, we will pay attention to the temperature, especially the high-temperature effect on the mechanical properties of graphene with the GBs. We perform classic MD simulations to investigate the elongation process of graphene with the GBs at different temperatures. In particular, we will pay more attention to the GB behaviors in the stretching process at high temperature and the corresponding physical mechanism of them at high temperature and under large stress.

The rest of this paper is organized as follows. In Section 2, we will give our calculation method and MD simulation details. In Section 3, the MD results and discussion are presented. Finally, in Section 4, we give the summary and conclusions.

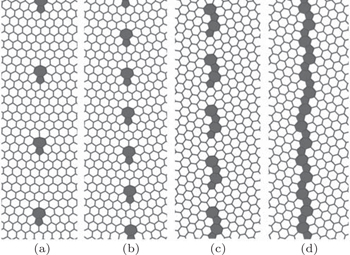

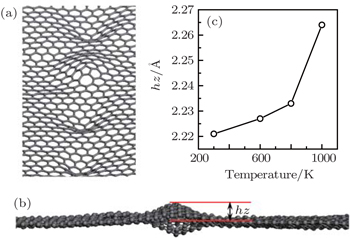

We use the software packages of Large-Scale Atomic/Molecular Massively Parallel Simulator (LAMMPS) to perform the MD simulations. Following the GB definitions in Ref. [10], the GB geometric structures used in our work at two different tilt angles for the zigzag or armchair orientation are shown in Fig.

Each sample contains about 6000∼7000 atoms with its size being about 90 Å in width and 200 Å in length. A periodical condition is used along the GB’s direction. Adaptive intermolecular reactive empirical bond order (Airebo) potential is used to describe the interaction between carbon atoms, in which the smaller cutoff distancercc is chosen to be 1.92 Å to follow what was used in Refs. [10] and [11]. Before we perform the MD simulations, each sample is relaxed using the MD method. The stretching direction is perpendicular to the grain boundary, and the stretching velocity is set to be 0.005% per picosecond, which follows the case in Refs. [10] and [11]. In the stretching process, the graphene sheet is allowed to shrink along the GB direction. All the MD simulations are performed using NVT ensemble.

The stress on a single carbon atom could be obtained by Virial stress expression.[27,28] Once the stress value on each carbon atom is calculated, we average it over the whole sample every 0.5 ps in the second half of the total relaxation time of 5 ps in order to obtain the stress of the entire system as also used in Refs. [10] and [11].

The graphene sheets with different grain boundaries are stretched at different temperatures until a crack occurs. As an example, the stretching curves at different temperatures for two different GBs shown in Fig.

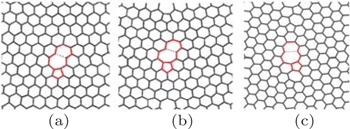

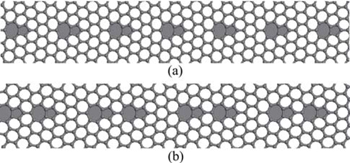

The geometric structures of the graphene sheets with different GBs just before the sample cracking at room temperature are shown in Fig.

From Fig.

Furthermore, we study the graphene sheet with mixed type GBs, namely, composed of both ZZ-GB and AC-GB. Figure

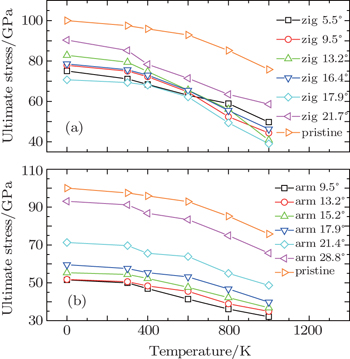

We give the relationships between the ultimate stresses of pristine graphene sheets and ones with various kinds of GBs at different temperatures in Fig.

As is well known, for the samples with AC-GBs, their ultimate stresses increase with their tilt angles at zero temperature, which is almost kept at different temperatures, even at very high 1000 K. But, for the ZZ-GBs, although their varying behaviors of ultimate stresses with their tilt angles at the lower temperatures, e.g., less than 600 K, can keep the same as those of them at T = 0, when T further increases up to higher than 600 K, the situation will become different because the dropping of the velocity of the ultimate stress εc with T increasing for the samples with a lower tilt angle of θ = 5.5° becomes lower than those of the samples with the higher tilt angles of 9.5° 13.2°, and 16.4° when the temperature is higher than about 700 K, which makes εc value at θ = 5.5° become larger than those at the larger tilt angles of 9.5°, 13.2°, and 16.4° when T > 700 K.

In order to know clearly the temperature effect on the mechanical properties of graphene sheets with various GBs at different mismatch angles, we study the relationships between ultimate stress and tilt angle at different temperatures. Our MD simulation results for both the zigzag- and armchair-oriented GBs are shown in Figs.

| Fig. 6. Plots of ultimate stress versus tilt angle for (a) zigzag-oriented GBs and (b) armchair-oriented GBs at different temperatures. |

The GB at 13.2° is composed of an array of uniformly distributed disclination dipoles, in which each dipole is a 5/7 defect; while at 16.4° the GB is composed of an array of disclination dipole cluster which is composed of two 5/7 defects. Reference [11] pointed out that the stress induced by disclination cluster is much greater than that by the disclination dipole. So the ultimate stress at tilt angle 16.4° is smaller than that at 13.2° showing a sharp decrease in the curve of ultimate stress with tilt angle increasing. Furthermore, it is seen clearly from Fig.

| Fig. 7. Sketch maps of graphene sheets with zigzag-oriented GBs at (a) tilt angle of 13.2° and (b) 16.4°. |

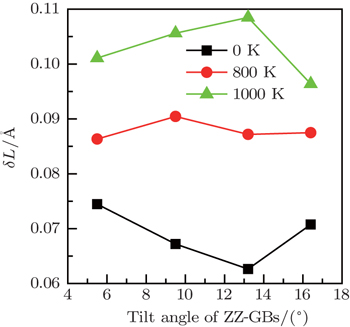

As explained in Refs. [10] and [11], the maximum initial inner strains in the bonds shared by the heptagon and hexagon rings in GBs of the samples with different tilt angles determine their final ultimate stresses. The larger the bond initial inner strain, the smaller the final ultimate stress is. As is well known, the C–C bond length in pristine graphene without an external strain is 1.42 Å. The topological defects (5/7 pairs) in the GBs of graphene would induce the initial inner strains of the C–C bonds in the sample, e.g., those shared by the heptagon and hexagon rings in GBs, which would be different at different mismatch angles. Following the definition in Ref. [12], the initial inner strain could be expressed by a relative C–C bond length of δL = L − L0, where the L0 = 1.42 Å and L is the mean value of the bond shared by the heptagon and hexagon rings. Therefore, the longer the δL, the larger the bond inner strain is. In order to investigate the temperature effect on the maximum initial inner strain in GBs, the mean values of the initial relative bond lengths δL for the ZZ-GBs at θ ≤ 16.4° are calculated at different temperatures without an applied strain and the obtained results are shown in Fig.

Finally, we focus our attention on the temperature effect on GB per se. As the temperature increases, the structure of GB does not show obvious change. However, due to the existence of GB, the surface of the graphene sheet is not strictly flat (see Fig.

From our MD simulation results, it can be concluded that the finite temperature has large effects on mechanical properties of graphene sheets with various GBs. Firstly, the ultimate stresses for both samples with ZZ-, AC-orientation and mixed type GBs decrease with increase of temperature. Secondly, the initial inner strains on those C–C bonds shared by heptagon and hexagon rings in ZZ-GBs without an applied external strain exhibit different values, depending on temperature and also mismatch angle. It is just the values of the initial inner strains to be found that determine the final ultimate stresses of the sample with ZZ-GB at different temperatures, especially at higher T ≥ 800 K and smaller tilt angles θ ≤ 13.2° for the ZZ-GBs. In contrast, for the samples with AC-GBs, the finite temperatures are found to have only less effects on the system mechanical properties, making only the ultimate stress values at different tilt angles to decrease with increasing temperatures. Finally, the height of ripple induced by GB in graphene sheet becomes high when temperature rises.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 |