† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 11375160) and the National Science Instruments Major Project of China (Grant No. 2012YQ130125).

Spectral diagnosis of radiation from laser plasma interaction and monochromation of radiation source are hot and important topics recently. Grating is one of the primary optical elements to do this job. Although easy to fabricate, traditional diffraction grating suffers from multi-order diffraction contamination. On the other hand, sinusoidal amplitude grating has the nonharmonic diffraction property, but it is too difficult to fabricate, especially for x-ray application. A novel nonharmonic diffraction grating named random position rectangle grating (RPRG) is proposed in this paper. Theoretical analysis and experiment results show that the RPRG is both higher order diffraction suppressing and not difficult to fabricate. Additionally, it is highly efficient; its first order absolute theoretical diffraction efficiency reaches 4.1%. Our result shows that RPRG is a novel tool for radiation diagnosis and monochromation.

As a dispersion optical element, diffraction grating is widely used in radiation diagnoses and source monochromation, and it plays an important role in studying inertial confinement fusion (ICF).[1–3] It is well known that ordinary diffraction grating has inevitable multi-order diffraction and this leads to harmonic spectral measurement error.[4] Ideal sinusoidal transmission grating (STG) is an excellent option to solve the multi-order diffraction contamination, which has only 0th and 1st order diffractions, since its transmittance function is an ideal sinusoidal function.[5,6] However, the ideal STG is too difficult to fabricate for its sinusoidal structure, especially for x-ray regime.

Based on the STG theory, Cao et al. have proposed several types of binary sinusoidal transmission gratings[7–15] since 2007. All these binary sinusoidal gratings with nonharmonic diffraction are composed of lots of small size units or complicated structures. The transmission functions of these nonharmonic diffraction gratings are all quasi-sine functions to realize the single-order diffraction. The structures of these nonharmonic diffraction gratings are complicated or the number of the structure units is very large. Therefore, they are difficult in fabricating the high line density grating. Here, we report random position rectangle grating (RPRG) which is designed to overcome these disadvantages. The fabrication of RPRG is much easier than the binary sinusoidal gratings mentioned above[7–15] while the property of high-order diffraction restraint is kept. Its 1st-order theoretical absolute diffraction efficiency is as high as 4.1%, far above all binary sinusoidal transmission gratings.

The basic structure of RPRG is similar to traditional grating, as shown in Fig.

According to the Fraunhofer diffraction theory, the far-field diffraction pattern is the Fourier transform of the transmission function. Hence, the Fourier series coefficients of the transmission function can give all the diffraction order efficiencies.

Along the grating period direction, the nth grating bar coordinate can be written as

Finally, the transmission function of the RPRG along the grating period direction is

The Fourier series coefficients of the transmission function t(x) are

The diffraction efficiency of mth diffraction order is ηm = |Fm|2, and

The theoretical analysis shows that the diffraction efficiencies of the 0th, 1st, 3rd, 5th diffraction orders of RPRG are 25%, 4.1064%, 0.0507%, and 0.0066%, respectively, and all even-order diffractions vanish. The diffraction efficiency ratios of the 1st to the 3rd and 5th diffraction are 81 and 625, which are much higher than the ordinary grating diffraction efficiency ratios which are 9.0 and 25.0. It shows that the RPRG can restrain the high-order diffraction.

Then, we change the duty ratio of RPRG to optimize the diffraction efficiency of the 1st order. The diffraction property can be analyzed through the process and the rn and the xn are the same as above. The transmission function of RPRG with duty ratio t in range (0, 1] is

The Fourier series coefficients of the transmission function t(x), or in other words, Fm (for large N) are

Duty ratios can be chosen as t = 1/2, 1/3, 1/4, and so on. The diffraction efficiencies of the 0th, 1st, 3rd, 5th diffraction orders for t=1/2, 1/3, 1/4, respectively, are listed in Table

| Table 1. The efficiencies of the 0th, 1st, 3rd, 5th diffraction orders for t = 1/2, 1/3, 1/4. . |

According to Table

In this paper, for the maximum diffraction efficiency, the RPRG with duty ratio t = 1/2 was verified by simulation and experiment.

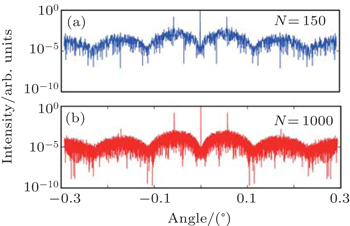

From the theoretical analysis above, as long as the number of illuminated grating periods N is a large number, our RPRG model should agree well with the theoretical result that was obtained at large N limit. To estimate the effect of N in the performance of RPRG, we carried out a simulation which includes two cases, one case has N = 150 and the other N = 1000, the former case has an N that is not really large compared to the latter case. The grating period d = 10 μm and the duty ratio of 0.5 are the same in both cases. Our simulation model of RPRG is shown in Fig.

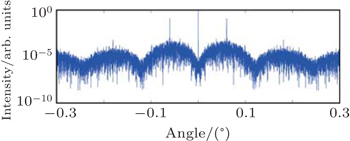

Considering balancing the visible RPRG manufacture and the RPRG design, the tolerance interval of the adjacent grating ridges with 500 nm and the variance of grating period with 500 nm have been simulated. The number of the simulation RPRG periods is N = 1000. The simulation results (as shown in Fig.

| Fig. 4. Diffraction result with the tolerance interval 500 nm and the grating period variance 500 nm, and N = 1000. |

To verify our theoretical analysis and simulation results, a visible light RPRG experiment was performed. The adopted RPRG was fabricated through lithograph technology in the Institute of Microelectronics, Chinese Academy of Sciences. The period of tested RPRG d is 10 μm and its duty ratio is 0.5. The experimental layout is shown schematically in Fig.

In this paper, a novel nonharmonic diffraction grating named RPRG is proposed. Through theoretical analysis, numerical simulation and the visible wavelength experiment, we have demonstrated that the RPRG with duty ratio 1/2 can restrain high-order diffraction and keep a high diffraction efficiency of the ±1 order diffraction of 4.1%. The designed grating overcomes the pre-proposed single-order grating fabrication difficulty. This novel grating is a potential key optical element for spectral measurement and x-ray, visible light monochromatization.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 |