† Corresponding author. E-mail:

Project supported by the Hi-Tech Research and Development Program of China (Grant No. 2013AA050302), the National Natural Science Foundation of China (Grant No. 61474065), Tianjin Municipal Research Key Program of Application Foundation and Advanced Technology, China (Grant No. 15JCZDJC31300), the Key Project in the Science & Technology Pillar Program of Jiangsu Province, China (Grant No. BE2014147-3), and the Specialized Research Fund for the Ph. D. Program of Higher Education, China (Grant No. 20120031110039).

Phosphorous-doped hydrogenated nanocrystalline silicon oxide (n-nc-SiOx:H) films are prepared via radio frequency plasma enhanced chemical vapor deposition (RF-PECVD). Increasing deposition power during n-nc-SiOx:H film growth process can enhance the formation of nanocrystalline and obtain a uniform microstructure of n-nc-SiOx:H film. In addition, in 20s interval before increasing the deposition power, high density small grains are formed in amorphous SiOx matrix with higher crystalline volume fraction (Ic) and have a lower lateral conductivity. This uniform microstructure indicates that the higher Ic can leads to better vertical conductivity, lower refractive index, wider optical band-gap. It improves the back reflection in a-Si:H/a-SiGe:H tandem solar cells acting as an n-nc-SiOx:H back reflector prepared by the gradient power during deposition. Compared with the sample with SiOx back reflector, with a constant power used in deposition process, the sample with gradient power SiOx back reflector can enhance the total short-circuit current density (Jsc) and the initial efficiency of a-Si:H/a-SiGe:H tandem solar cells by 8.3% and 15.5%, respectively.

Thin film solar cells, especially silicon-based, provide a highly potential alternative for the massive demand of photovoltaic modules, and a lot of efforts are made to increase their stable efficiencies. Among many factors, light management and cell structure play critical roles in improving cell performance.[1,2] During recent years, nanocrystalline silicon oxide (nc-SiOx:H) films with low absorption and low refractive index have been successfully prepared and used as key functional layers in thin-film silicon solar cells. For instance, this film has been proposed to be used as a window layer in n or p-side illuminated silicon solar cells,[3–7] the a-Si:H solar cell efficiency reaches up to 10.2%. The intermediate reflector (IR) in multi-junction solar cells achieved 13.6% efficiency of a-Si:H/nc-Si:H tandem solar cell.[8–14] For the back reflector (BR) in thin-film silicon solar cells,[13–16] and an extra thin resistive layer or alternative n-layer,[11,15] an above 11% of efficiency of a-Si:H/a-SiGe tandem solar cells has been achieved. The doped nc-SiOx:H film is a mixed phase material which has an oxygen rich amorphous silicon oxide (a-SiOx:H) phase and a doped nanocrystalline silicon (nc-Si:H) phase.[16,17] Consequently, its optical band gap (E04), which is defined as the photon energy gap at which the absorption coefficient α equals 1 × 104 cm−1, and refractive index can be precisely tuned by the O-content inside the a-SiOx:H phase. Therefore, the doped nc-SiOx:H film combined with a suitable conductivity as p-type or n-type doped nanocrystalline silicon (nc-Si:H) phase can serve as a replacement for the conventional doped layers in thin-film silicon tandem solar cells to enhance both the optical and electrical properties. In addition, to achieve highly stable efficiency, two or more junction tandem solar cells with interlayer between sub-cells are necessary, where SiOx material was also employed and also showed a better result than ZnO.[14,18] Consequently, the preparation of a doped nc-SiOx:H film, which has wider optical band-gap, lower refractive index, and higher conductivity, is a key process to improve the performances of thin-film silicon tandem solar cells. The microstructure of a doped nc-SiOx:H film is a very important factor that can regulate these characteristics, and many deposition parameters also control the structure, such as deposition power and hydrogen dilution.[10,12]

In this study, we report on such a material development for n-type nc-SiOx:H (n-nc-SiOx:H) films and focus on the deposition power as a crucial parameter in the radio frequency plasma enhanced chemical vapor deposition (RF-PECVD). In comparison with conventional SiOx material fabricated in a fixed deposition power, an optimized structure is proposed by introducing gradient deposition power with or without interval time in an n-nc-SiOx:H film deposition process. Finally, this optimized structure of n-nc-SiOx:H film is successfully used in a-Si:H/a-SiGe:H tandem solar cells as a BR and the results show its great enhancement over cell performance.

The n-nc-SiOx:H films were prepared in a PECVD multi chamber system using an excitation frequency of 13.56 MHz on Corning Eagle XG glass substrates with a temperature of approximately 190 °C. The process gases used were carbon dioxide (CO2), hydrogen (H2), and 10% silane (SiH4) diluted in H2, and phosphine (PH3) as n-type dopant source. Deposition parameters such as H2 dilution (H2-fiow/SiH4-flow), doping concentration (PH3-flow/SiH4-flow) and chamber pressure were fixed to be 68.7, 3%, and 85 Pa, respectively. The power was varied during the deposition to control the optical and electrical properties. The details can be seen in Table

| Table 1. Deposition parameters of n-nc-SiOx:H films and the solar cell samples which use corresponding films. . |

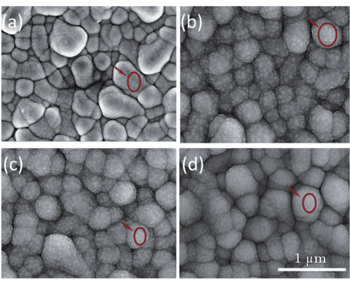

The structural, electrical, and optical properties of the films were investigated by Raman spectroscopy (λ = 488 nm), scanning electron microscopy (SEM), dark conductivity measurements, and optical transmission spectrum. To evaluate the properties of n-nc-SiOx:H films, mass-produced level amorphous silicon/amorphous silicon–germanium (a-Si:H/a-SiGe:H) double junction tandem solar cells were selected as reference devices.

The crystalline volume fraction of the film was probed by Renishaw via Raman reflex spectrometer using the 488-nm line of an Ar laser. The dark conductivity (σd) was measured by using coplanar Al-electrode at 300 K, which characterizes the lateral conductivity, and the film thickness was measured by surface step profilometer. Optical transmission spectra were obtained by using Cary spectrophotometer. The morphology of the n-nc-SiOx:H film surface at the tandem solar cells was achieved by scanning electron microscopy (SEM). The photovoltaic parameters of the solar cells, which were all patterned to an area of 0.25 cm2, were measured under standard test condition (STC): AM1.5G, 300 K and 100 mW/cm2, and the external quantum efficiency (EQE) was also calculated from the spectral response measured.

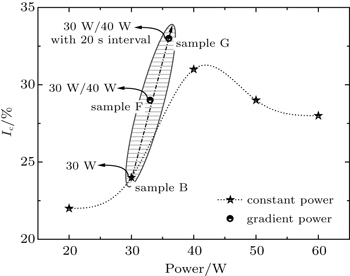

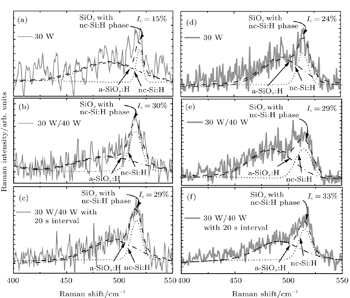

The Raman scattering spectra are de-convoluted into two Gaussian-shaped peaks: (i) the transverse optical (TO) mode of the a-SiOx:H phase (centered around 480 cm−1) and (ii) the TO vibrational mode of the nc-Si:H phase (centered around 520 cm−1).[19] The crystalline volume fraction of the n-nc-SiOx:H film is defined as the Raman intensity ratio Ic which is equal to the ratio of the integrated area of the nc-Si:H peak to the total peak area (a-SiOx:H + nc-Si:H) as given in the following equation:

Figure

Figure

From the Raman spectra shown in Figs.

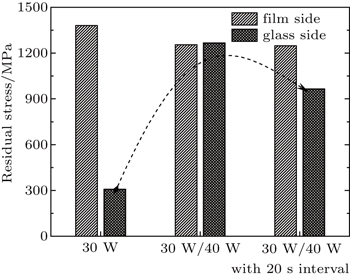

| Fig. 3. Variations of residual stress of the deposited n-nc-SiOx:H films with power from film side and glass side, respectively. |

It is evident from Fig.

Figure

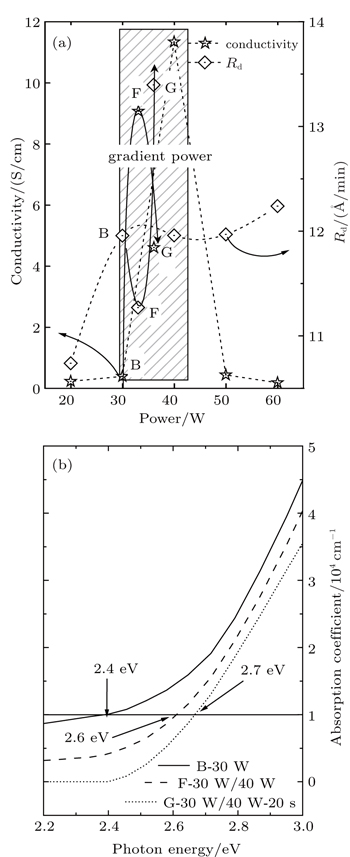

The oxygen-rich region in n-nc-SiOx:H film, totally amorphous, supplies low refractive index and high band gap because of incorporated oxygen;[21] the n-doped nanocrystalline silicon region provides sufficient electrical conductivity.[22,23] The influences of deposition parameters on lateral conductivity and growth rate are presented in Fig.

| Fig. 5. Average deposition rate (Rd) and lateral conductivity (a), absorption coefficient and n, k (b) of the different n-nc-SiOx:H films. |

The optical properties of the n-nc-SiOx:H films are also studied. Figure

Figure

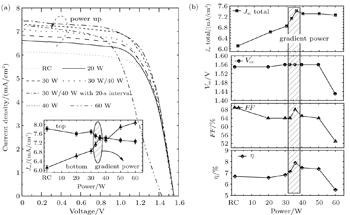

| Fig. 6. (a) J–V curves of solar cells, the inset showing the top cell and bottom cell’s Jsc tendency, and (b) the parameters of the solar cell. |

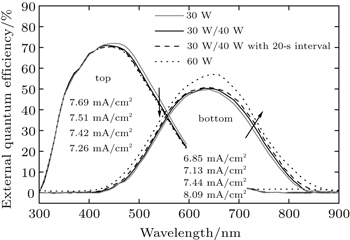

The variations of external quantum efficiency (EQE) of a tandem cell with wavelength for different n-nc-SiOx:H serving as BRs are shown in Fig.

In the present work, each of n-nc-SiOx:H films prepared under a gradient deposition power is used as a back reflector in a-Si:H/a-SiGe:H solar cell. Based on the Raman and SEM results, the crystallinity volume fraction increases (approximately 33%) with gradient power increasing in a n-nc-SiOx:H film deposition process. Because the etching effect of H atoms is larger than the dissociation efficiency of CO2, the mixing uniformity of n-nc-SiOx:H film is improved. The dark conductivity confirms that increasing deposition power in the deposition process of n-nc-SiOx:H film raises the lateral conductivity considerably (from 0.4 S/cm to 9.1 S/cm) and the higher dissociation efficiency of CO2 leads to the lower α, n, and k. In addition, the lowest α, n, and k of the n-nc-SiOx:H film are obtained by 20-s interval before power change. The lateral conductivity of film drops to 4.6 S/cm for the higher potential energy. The Jsc of a-Si: H/a-SiGe:H solar cell with this optimized SiOx BR increases from 6.85 mA/cm2 to 7.42 mA/cm2, because the higher refractive index step enhances the light trapping of the long wavelength in the absorbing layer and then improves the cell efficiency. In conclusion, this n-nc-SiOx:H film with proper optical properties and optimized lateral conductivity improves the performance of the a-Si:H/a-SiGe:H solar cell significantly.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 | |

| 30 |