† Corresponding author. E-mail:

Project partly supported by the National Basic Research Development Program of China (Grant No. 2010CB327604), the National Natural Science Foundation of China (Grant No. 61377100), and the Natural Science Foundation of Guangdong Province, China (Grant No. S2013040015665).

In this paper, a novel birefringent photonic crystal fiber (PCF) with the silver-coated and liquid-filled air-holes along the vertical plane is designed. Simulation results show that the thickness of silver layer, the sizes of holes, and the refractive index of liquid strongly strengthen the gaps between two polarized directions. The surface plasmon resonance peak along y axis can be up to 675.8 dB/cm at 1.33 μm. The proposed PCF has important application in polarization devices, such as filters and beam splitters.

Photonic crystal fibers (PCFs) have been involved in many research areas since their initial fabrication,[1,2] due to their high birefringence,[3] high nonlinearity,[4] and controllable dispersion.[5] Recently, new application of PCFs has been explored. For instance, by filling the cladding holes with gases, liquid crystals, and red blood cells, they can be applied to the chemical sensing and photochemistry,[6] polarization devices,[7] and single-cell biomechanics.[8]

In the previous reports, to achieve the polarization effects, common methods were used to change the air-hole diameters along two orthogonal directions[9,10] or using different materials.[11] Wei et al. demonstrated a birefringent PCF with a tellurite glass T2 doped ellipse core, reaching the birefringence of 7.66 × 10−2 and nonlinearity of 3400 W−1·km−1 around 1550 nm.[12] These studies focused on obtaining the high refractive index difference between the fundamental modes at x axis and y axis.

Recently, the surface plasmon resonance (SPR) which depends on the phase matching between the incident light and SP wave, shows wide application to improve the sensitivity of optical area, such as enhancing emission of SLED to realize high power[13,14] based on the SPs’ electric field localization and enhancement characteristics. Lee et al. reported the polarization-dependent characteristics of a polarization maintaining PCF with gold wires.[15] Schmidt et al. analyzed the surface plasmon modes in the PCFs with the metal nanowire-filled PCFs, which was fabricated by the high-temperature pressure-cell.[16,17] Yu et al. simulated a selective coating of PCF with metal for SPR sensing.[18] Uebel et al. demonstrated a gold nanowire array in a PCF, where the radial electric field was resolved by a polarization sensitive near-field probe.[19] Xue et al. demonstrated a gold-coated and liquid-filled PCF, where one-side SPR was up to 508 dB/cm.[20] Liu et al. reported a PCF for two kinds of filters with the nanoscale gold film, the extinction ratio (ER) reaches to −20 dB.[21] Fan et al. numerically simulated the D-shaped PCF with gold-filled holes for the filter, gaining 292.8 dB/cm at y polarization axis.[22] Most reports mentioned above mainly concentrated on gold filling or coating, less coating processing due to more difficulty.

Compared to the gold, the cheaper silver shows some benefits, such as better thermal conductivity, easier to generate high-order mode, and relatively easy coating processing. Zhang et al. coated the silver in the air-holes and fabricated an in-fiber absorptive polarizer.[23] Bing et al. simulated and fabricated an SPR-PCF with silver-coated holes for sensor,[24] and yet, the research of silver-coating processing for PCF filter is uncommon, so we do the relative research in the hope of offering theoretical results on the silver-coated PCF for filter research and application.

In this paper, the polarization properties of a silver-coated birefringent structure PCF with water-filled holes in air holes along the y-polarized direction is studied by the finite element method (FEM). The simulation results show that the position and strength of the resonance peak are strongly influenced by the metal thickness and the cladding hole size.

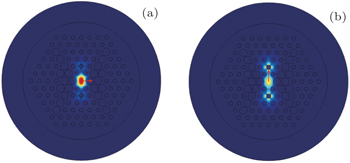

The cross-section of the PCF designed is shown in Fig.

The background material is the pure silica whose material dispersion is calculated by Sellmerier formula.[25] In the finite element simulation, an anisotropic perfectly matched layer (PML) is employed. The material dispersion of silver is dependent on the Lorentz–Drude model,[26] which is defined as

The absorption losses of water and ethanol are very low within the considered range, so it is not necessary to consider their material dispersion in the next calculation. Their refractive indices are defined as nwater = 1.33 and nethanol = 1.36. The confinement loss is defined as

Recently, the PCF fabrication processing consists of ultrasonic drilling, stacking, and so on. For coating methods, one way is suction and evaporation of the metal-nanoparticle mixtures into the fiber, and another is chemical vapour deposition (CVD). Moreover, for the silver, the chemical deposition has been usually used in the research depending on the adjusting reaction conditions for silver deposition.[23]

When the real part of surface plasmon polariton (SPP) modes coincides with the core guided modes neff, the energy will be transferred from the core region to the silver-coated layer, leading to a visible energy leak and sudden increase of the confinement loss. Figure

As seen from Fig.

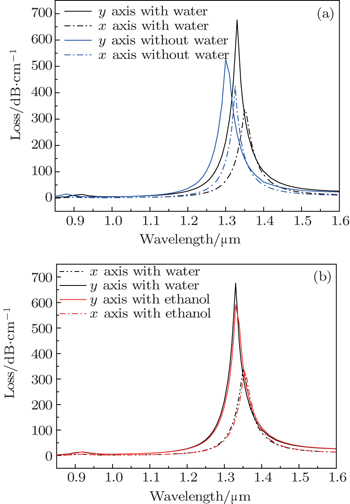

We inject the liquid into the silver-coated air-holes, and the impact of the liquid is presented in Figs.

| Fig. 4. Impact on the presence of liquid (a) and the types of liquid (b) in the silver-coated holes. |

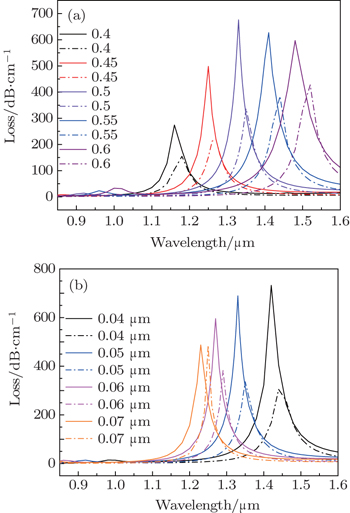

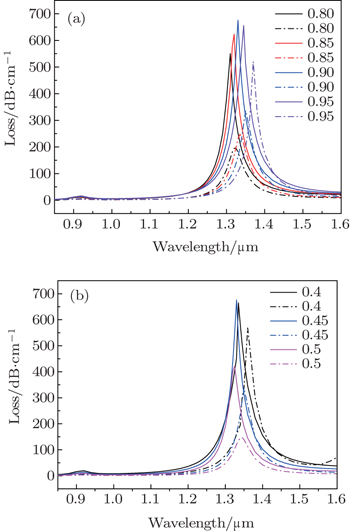

Below the birefringent structure and the thickness of the silver-coated layer will be analyzed. As introduced before, the birefringence influence could cause the expanding gap of neff between the two sides, the different SPR wavelength, and the much stronger SPR strength along y axis. Hence, the dependence of birefringence on the sizes of the diameters d1, d2, which is such that birefringence increases with the enlarging of d1 or the decrease of d2, is analyzed in Fig.

| Fig. 5. Variation effects of d1/Λ (a) and d2/Λ (b) on the loss, the solid and dashed lines are the loss of core guided modes along y-polarized and x-polarized directions, respectively. |

The influence of d2/Λ on the loss is presented in Fig.

The birefringent structure shows a weaker impact on the position of resonance wavelength, but it strongly affects the resonance peak. The structure offers a stronger resonance peak and a suitable resonance wavelength, when parameters Λ, d1/Λ, d2/Λ, and d3/Λ are fixed at 2 μm, 0.9, 0.45, and 0.5, respectively.

Due to the strong effect of the silver-coated hole size and silver thickness on the resonance wavelength, the outside diameter of silver-coated holes d3 is studied. As shown in Fig.

As mentioned in the previous section, the coating process could possess an economical metal cost and more importantly, the resonance strength is much stronger than that filled in Ref. [20], so the dependence of the loss on R is also analyzed, as shown in Fig.

In summary, a novel silver-coated and liquid-filled PCF is designed, and the resonance peak at 1.33 μm can be up to 675.8 dB/cm along the y-polarization direction. The simulation results show that the polarization properties are determined by the air-hole size and the silver layer thickness. The proposed PCF shows a significant difference of the resonance peaks between two directions within the studied wavelength range, which will have important application in polarization devices.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 | |

| 21 | |

| 22 | |

| 23 | |

| 24 | |

| 25 | |

| 26 | |

| 27 | |

| 28 | |

| 29 | |

| 30 |