† Corresponding author. E-mail:

Project supported by the National Natural Science Foundation of China (Grant No. 61504107) and the Fundamental Research Funds for the Central Universities, China (Grant Nos. 3102014JCQ01059 and 3102015ZY043).

We demonstrate that the insertion of a graphene tunnel barrier between Heusler alloy Co2MnSi and the germanium (Ge) channel modulates the Schottky barrier height and the resistance–area product of the spin diode. We confirm that the Fermi level is depinned and a reduction in the electron Schottky barrier height (SBH) occurs following the insertion of the graphene layer between Co2MnSi and Ge. The electron SBH is modulated in the 0.34 eV–0.61 eV range. Furthermore, the transport mechanism changes from rectifying to symmetric tunneling following the insertion. This behavior provides a pathway for highly efficient spin injection from a Heusler alloy into a Ge channel with high electron and hole mobility.

The injection of spin-polarized electrons into semiconductor channels has attracted considerable interest recently.[1–3] To realize highly-efficient spin injection from a ferromagnetic electrode into a semiconductor channel, a highly-polarized spin injection source and a high-mobility semiconductor channel are required. The Heusler alloy Co2MnSi is a promising candidate as a spin injection source because of its theoretically predicted half-metallicity, that is, 100% spin polarization at the Fermi energy.[4] Indeed, Jourdan et al. have directly observed half-metallicity in the Heusler compound Co2MnSi in experiment.[5] Furthermore, germanium (Ge) is one of the promising semiconductor candidates because of its high bulk mobility for both electrons and holes. Thus, the combination of Co2MnSi and a Ge channel is expected to yield highly-efficient spin injection into Ge. However, in a ferromagnetic material (FM)/Ge junction, the acceptor- and donor-like interface states in the Ge can be easily occupied by carriers penetrating the material from the FM, which can lead to the accumulation of dipole moments at the interface.[6] Thus, the Fermi level can be pinned near the charge neutrality level (CNL).[6] As the CNL of Ge is close to the valence energy band, the Schottky barrier height (SBH) of the FM/Ge junction has a weak dependence on the metal work functions and the SBH of the FM/Ge junction is relatively large, resulting in a high resistance–area (RA) product. The realization of an FM/Ge junction with a low RA product is important for various Ge-based spintronic devices.

The previous reports have suggested that the insertion of a thin insulator between an FM and the Ge is a possible method for achieving Fermi-level depinning.[7–9] Here, depinning refers to the shift of the Fermi level relative to the original strong pinning position. However, the thin-insulator defects and amorphous state could lead to an inhomogeneous interfacial structure as well as variations in the bulk film quality and thickness, all of which introduce complications to the investigation of the origin of the Fermi-level pinning.

Graphene is a potential candidate for the insulator tunneling barrier for two primary reasons: (i) it provides a highly uniform, defect-free, and thermally stable thin layer (graphene has been shown to successfully prevent interdiffusion between a ferromagnetic material and a semiconductor annealed at high temperature);[10] and (ii) it exhibits poor conductivity perpendicular to the plane, although it is very conductive in-plane.[11] Cobas et al. have fabricated graphene-based magnetic tunnel junctions, in which the graphene functions as a tunnel barrier, thereby demonstrating clear magnetoresistance curves at room temperature.[12] Recently, van’t Erve et al. have reported that graphene can serve as a tunnel barrier for the spin injection from a NiFe thin film into a Si substrate using a three-terminal circuit geometry.[13] To date, however, very few studies have been published on the electrical properties of the Heusler alloy Co2MnSi/graphene/Ge heterostructure.

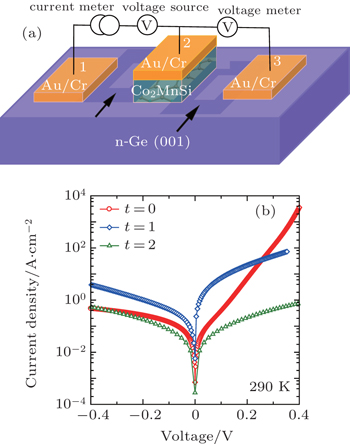

In the present study, we aim to investigate the effect of the graphene tunnel barrier in a Co2MnSi/graphene/Ge junction on the SBH. For this purpose, Co2MnSi thin films on Ge (001) substrates with graphene layers inserted are prepared using magnetron sputtering (for Co2MnSi thin films) and chemical vapor deposition (CVD, for graphene layers). The junctions are prepared using conventional photolithography and Ar milling, and the current versus voltage (I–V) characteristics of each junction are measured using a three-terminal circuit geometry. Subsequently, the thermionic emission model is used to quantitatively analyze the effect of the number of graphene layers on the SBH of the Co2MnSi/graphene/Ge heterostructure.

This paper is organized as follows. Section 2 describes the experimental methods; Section 3 presents our experimental results regarding the J–V characteristics of the Co2MnSi/graphene/Ge (001) heterostructures and an accompanying discussion; and Section 4 contains a summary of our results and conclusions.

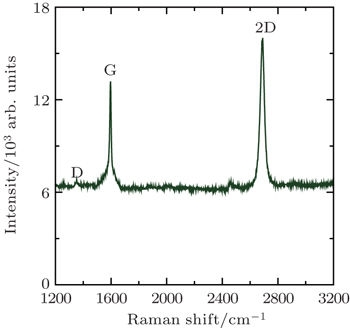

The layer structure examined in this study was comprised of (from the substrate side) graphene/Co2MnSi (20 nm)/Ru cap (5 nm) on a Ge (001) single-crystal substrate. The Ge substrate used here was an n-type as-doped substrate with 5 mΩ·cm resistivity. Following the removal of the native oxide using a diluted hydrofluoric acid solution, the substrate was cut into specimens with areas of 25 mm× 25 mm. The graphene was fabricated using CVD on a copper foil, and the resultant graphene/copper foil specimen was cut to sizes of 20 mm× 20 mm. The graphene surface was coated with photoresist to assist the subsequent wet-transfer process. The graphene/copper foil was immersed into ferric trichloride so that the copper was removed completely through etching, and the photoresist-coated graphene was then physically transferred onto the Ge (001) substrate. The sample was cleaned using a hydrofluoric acid solution, the photoresist was removed with acetone, and the resultant sample was finally washed using deionized water.

For samples requiring the transfer of two layers of graphene, once the first layer had been transferred, the photoresist was removed using acetone. Then the next graphene layer was transferred. Samples featuring single and double layers of graphene were examined in this study.

The prepared graphene/Ge (001) substrate was installed in a high-vacuum chamber with a base pressure of 5.0×10−4 Pa and a 20-nm-thick Co2MnSi thin film was then deposited via magnetron sputtering at room temperature (RT). The sample was subsequently annealed in-situ at a temperature Ta of 400 °C. After growth, junctions with sizes ranging from 30 μm× 30 μm to 150 μm× 150 μm were fabricated via conventional photolithography and Ar milling. The Cr/Au was deposited directly on the Ge for ohmic contact with a specimen size of 250 μm× 250 μm. The I–V characteristics of each junction were measured using a three-terminal circuit geometry.

Figure

Figure

Figure

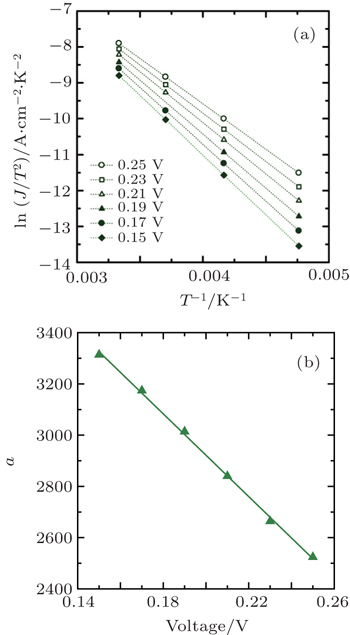

For a quantitative analysis of the effect of the graphene layer insertion on the SBH of the Co2MnSi/graphene/Ge junction, the thermionic emission model is adopted.[15] This model is expressed as

For V ≫ kT/q, 1 −exp(–qV/kT) ≈ 1 (kT/q = 18 eV–26 mV for T ranging from 210 K to 300 K). Thus, equation (

Figure

The SBH and n values of the Co2MnSi/graphene/Ge (001) junctions with different numbers of graphene layers are extracted and listed in Table

| Table 1. The Schottky barrier height and ideality factor (n) of Co2MnSi/graphene/Ge (001) junctions with different graphene tunnel barrier thicknesses. . |

It is well known that MIGS are formed by tailing of the wave function into the semiconductor band-gap. Therefore, it is very likely that tailing suppression due to the presence of the ultrathin graphene layer caused the change in the SBH. However, when two layers of graphene were inserted between Co2MnSi and the Ge channel, the tunneling dominated the transport mechanism. Thus, this result provides an evidence that the MIGS are the most plausible mechanism for the strong Fermi-level pinning at the Co2MnSi/Ge interface. As the graphene-layer thickness increases, the SBHs decrease significantly and the I–V characteristics become almost symmetric with respect to the bias polarity for the Co2MnSi/double-graphene (t = 2)/Ge junction, which is promising as regard to the realization of spin injection and detection from highly spin-polarized Co2MnSi thin films to Ge channels featuring high electron and hole mobility.

The effect of the inserted graphene layer on the Schottky barrier height of a Co2MnSi/graphene/Ge junction was investigated with one or two graphene layers. It was found that the Fermi level was depinned and the SBH was significantly decreased (from 0.61 eV to 0.34 eV) following the insertion of a graphene layer. Furthermore, the measured SBH depended on the number of graphene layers, which is consistent with the metal-induced gap states model. Our results demonstrate that graphene insertion can be useful for the realization of spin injection and detection from highly spin-polarized Co2MnSi thin films to Ge channels featuring high electron and hole mobility.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 |