† Corresponding author. E-mail:

To diminish the thermal load, two ways, that is, in-band direct pumping and micro-rod crystal, could be adopted at the same time. The efficiency of LD in-band direct-pumping side surface polished micro-rod Nd:YVO4 laser is numerically analyzed. By optimizing parameters such as crystal length, laser mode radius, pump beam radius, doping concentration and crystal cross-section size, the overall efficiency can reach over 50%. It is found that with micro-rod crystal implemented in the laser oscillator, high overall efficiency LD in-band direct-pumping Nd:YVO4 laser could be realized. High efficiency combined with low thermal load makes this laser an outstanding scheme for building high-power Nd:YVO4 lasers.

The neodymium-doped vanadate (Nd:YVO4) crystal is widely used as a laser medium in laser diode (LD) pumped solid-state laser due to its valuable properties such as polarized emission and high gain.[1,2] However, relatively poor thermal and mechanical characteristics strongly limit the pump power and the laser power, degrade the beam quality, or damage the crystal. Some ways were investigated to diminish the thermal load of the crystal. One way is to reduce the quantum defect with in-band direct pumping[3] to the upper lasing level such as at 880 nm[4] or 888 nm[5] instead of 808 nm. Splitting the thermal load with multiple crystals[6] is also a solution. Composite crystal[7,8] is another common method to relieve the thermal load. Changing the crystal shape into a disk,[9] or slab,[10] replacing the traditional rod is also an available option.

Single crystal fiber (SCF) is a long and thin crystal rod with a diameter usually smaller than 1 mm, a typical length of several centimeters and a cylindrical surface good enough to guide the pump beam by total internal reflection.[11] SCF is so designed that the laser beam propagates in the medium freely as does a traditional bulk laser, whereas the pump beam is guided by the thin crystal rod, which depends on the pump brightness.[12] Basically, single crystal fibers are grown by the laser heated pedestal growth technique.

Just like single crystal fiber, micro-rod crystal has a micro cross section with side surface polished good enough to guide the pump beam by total internal reflection and is a thin rod-shaped crystal whose cross section can be circular, elliptical, squared or other shapes. Micro-rod crystal possesses almost all the characteristics of single crystal fiber and has more cross section shapes to be chosen. The guiding characteristic of the pump beam enables longer gain medium with lower absorption coefficient to be used, resulting in reduced thermal load in the crystal. The large area-to-volume ratio of the micro-rod also diminishes crystal thermal load. The freely propagating property of the laser beam in the crystal facilitates the formation of a large mode area of the laser beam, which helps avoid non-linear effects. It is worth emphasizing that the micro-rod is processed mechanically as ordinary-sized crystal would be, which is different from SCF. The SCFs have been successfully implemented in Yb:YAG[13] and Nd:YAG[14] oscillators and pulsed Yb:YAG amplifiers. However, as we speculate, the Nd:YVO4 single crystal fiber which is suitable for high efficiency laser may be difficulty to grow, so the Nd:YVO4 single crystal fiber laser has not been reported so far.

To diminish the thermal load, two ways, that is, direct pumping and micro-rod crystal, could be adopted at the same time. Thin and long crystal can reduce thermal load but also reduce the overlap efficiency between laser mode and pump mode at the same time. What is the efficiency of LD in-band directly pumping micro-rod Nd:YVO4 laser? In this paper, the efficiency of LD in-band direct-pumping side surface polished micro-rod Nd:YVO4 laser is numerically analyzed. It is found that with micro-rod implemented in the laser oscillator, LD in-band direct-pumping high overall efficiency Nd:YVO4 laser could be realized. Its high efficiency and low thermal load make it an outstanding scheme for high-power Nd:YVO4 lasers.

Laser performance is typically characterized by slope efficiency. The slope efficiency σs of the output power versus input power curve is given as follows:[15]

The pump source spectral efficiency ηPS is the fraction of input optical power which is in the absorption region of the gain medium.

The optical transfer efficiency ηT is the ratio between the optical power incident on the gain medium and that emitted by the pump source.

The absorption efficiency ηα is the ratio of the power absorbed in the gain medium to the power of entering the gain medium. For diode pumped laser, the absorption efficiency can be approximated, and given below.

The quantum efficiency ηQ is defined as the number of photons contributing to laser emission, divided by the number of pump photons.

The quantum defect efficiency ηS is the Stokes factor which represents the ratio of the photon energy emitted at the laser to the energy of a pump photon, and expressed as.

The beam overlap efficiency ηB is defined as the resonator mode volume divided by the pumped volume of the active gain medium,[16] and described as

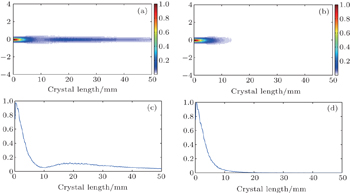

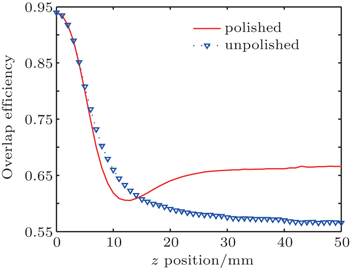

To obtain the beam overlap efficiency, a three-dimensional (3D) ray-tracing model is built to simulate optical intensity distribution in the active gain medium instead of a commonly used mathematical expression. For instance, it can be set that the micro-rod has a diameter of 1 mm, and is incident by a 888-nm Gaussian beam with a far field divergence angle of 0.11 and focal diameter of 400 μm in the front face of the crystal. The pump intensity distributions (normalized by the maximum of intensity) in the micro-rod crystal with side surface polished and traditional rod crystal with side surface unpolished are obtained respectively as shown in Fig.

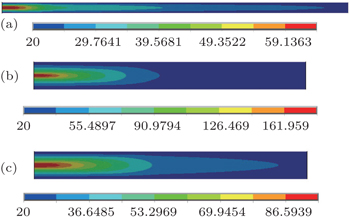

In order to compare the thermal effect of micro-rod crystal with that of traditional rod crystal, their temperature distributions are simulated. Large area-to-volume ratio makes the thermal effect of the micro-rod lower than that of traditional rod crystal, which is indicated in Fig.

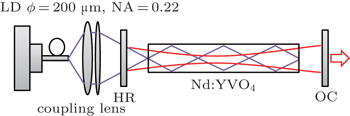

The schematic diagram of the simulated setup is shown in Fig.

Figure

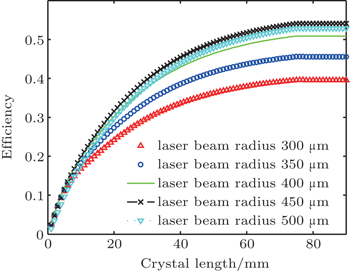

| Fig. 5. Overall efficiencies as a function of crystal length for different laser beam radii when the pump beam radius is 200 μm. |

Figure

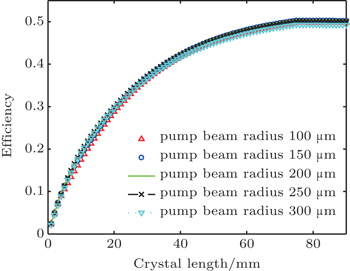

| Fig. 6. Overall efficiencies as a function of crystal length for different pump beam radii when the laser beam radius is 400 μm. |

Figure

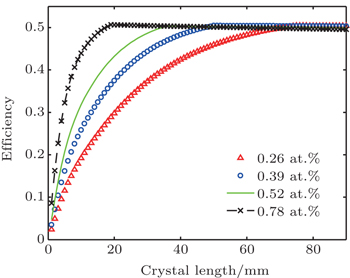

| Fig. 7. Overall efficiencies as a function of crystal length with different doping concentrations when the laser beam radius is 400 μm and the pump beam radius is 200 μm. |

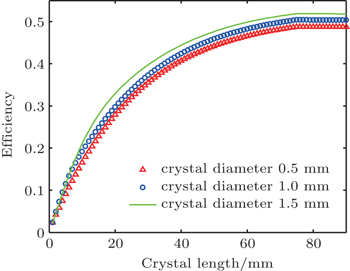

Figure

Comparisons of other published experimental results with numerical analyses are shown in Table

| Table 1. Comparison between experimental results and numerical analyses. . |

To diminish the thermal load, two ways, that is, in-band direct pumping and micro-rod crystal could be adopted at the same time. In-band direct pumping micro-rod Nd:YVO4 lasers have not been reported so far to our knowledge. In this paper, the efficiencies of LD in-band direct-pumping side surface polished micro-rod Nd:YVO4 lasers are numerically analyzed. By optimizing parameters such as crystal length, laser mode radius, pump beam radius, doping concentration and crystal cross-section size, the overall efficiency can reach over 50%. It is found that with micro-rod crystal implemented in the laser oscillator, high overall efficiency LD in-band direct-pumping Nd:YVO4 laser could be realized. High efficiency combined with low thermal load makes it an outstanding scheme for building high-power Nd:YVO4 lasers. The following work is the experimental study of LD in-band direct-pumping micro-rod Nd:YVO4 laser.

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 |