†Corresponding author. E-mail: kena@mans.edu.eg

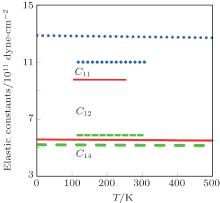

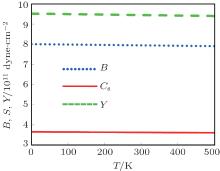

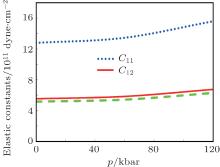

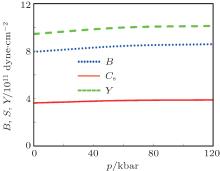

The mechanical properties, such as the elastic constants C11, C12, C44, and bulk, Young’s, and shear moduli, of a Ga xIn1 − xAs yP1 − y alloy lattice matching to a GaAs substrate are calculated for various As concentrations. The calculations are based on the pseudo-potential method within the virtual crystal approximation containing the effective disorder potential. The variations of the studied properties with pressure and temperature are investigated. A comparison between the calculated results and the available published data for binary parent compounds shows that they have good agreement, while the calculated results for the quaternary alloys at various temperature and pressure may be taken as a reference.

Quaternary semiconducting materials are of continuing major concern due to their various technical applications, including light emitting diodes, lasers, optical amplifiers, detectors, frequency mixing components, and electro-optic modulators.[1] The range of device applications has been broadened in the last few decades by increasing the possibilities of engineering the material properties. The quaternary alloy GaxIn1 − xAsyP1 − y is one of the alloys that are particularly important for manufacturing optoelectronic devices. The properties of a material under stress are determined by the elastic constants.[2] These properties have an important role in determining the binding characteristic between adjacent atomic planes, structural stability, and anisotropic characteristics of binding.[2] For the mechanical properties, a knowledge of the effect of strain on the electronic properties, specifically the elastic constants which describe the response to an applied macroscopic stress, is required.[3] Since the advent of nanodevices based on semiconductor materials, the detailed conceptions of these materials under the influence of temperature and pressure have been conveniently determined.[4]

In the present study, the elastic parameters and the relevant properties of GaxIn1 − xAsyP1 − y quaternary alloy lattice matching GaAs substrate are investigated in a composition (y) range of 0– 1, a temperature range from 0 to 500 K, and a pressure range from 0 to 120 kbar. The quaternary alloy GaxIn1 − xAsyP1 − y is consisted as the ternary alloys GaxIn1 − xAs, GaAsxP1 − x, InAsxP1 − x, and GaxIn1 − xP, which are bounded in their corresponding orders by four binary materials InAs, GaAs, InP, and GaP.

Our calculations are based on the empirical pseudopotential method (EPM) within the virtual crystal approximation (VCA) including the effective disorder potential.[5– 22] We also study the variations of the mechanical properties of interest for the GaxIn1 − xAsyP1 − y/GaAs system with temperatures and pressures. The calculated results for the binary parent compounds GaP, GaAs, InP, and InAs show good agreement with the available experimental and published data.

The rest of this paper is organized as follows. In Section 2, we briefly describe the calculation method. Our results and discussion are given in Section 3. And our conclusion is presented in Section 4.

Initially, the energy band gaps of the binary parent compounds GaAs, GaP, InAs, and InP are calculated by using EPM. In EPM, one needs to solve the Schrö dinger equation in which the one-electron pseudo-potential is represented by a linear superposition of the atomic potentials which are adjusted to fit well with the experimental values at the selected points L, Γ , and X in the Brillouin zone.

The band gap energies are estimated by numerically solving the secular determinant equation[12, 13]

where

is the Z-dependent pseudo-potential, and Z may be pressure p or temperature T.

The symmetrical Ws and anti-symmetrical Wa form factors of the parent binary compounds of GaxIn1 − xAsyP1 − y are deduced by fitting the calculated band gap energies to match the experimental values available in the literature. The temperature- and pressure-dependent form factors are obtained from the assumed relations[5, 6]

where

The temperature- and pressure-dependent lattice constants of the binary compounds are calculated from the following relations:[21]

where α th, B, and B′ are constants cited from Ref. [21].

The band gap energies of the parent binary compounds GaAs, InP, GaP, and InAs at different temperatures and pressures are displayed in Table 1. A comparison between our calculated data and the published ones show that they are in excellent agreement with each other. Table 2 shows the adjusted form factors of the binary materials GaAs, GaP, InP, and InAs for various temperatures and pressures.

The next step is to study the band gap energies of the associated ternary compounds, namely, GaxIn1 − xAs, GaAsxP1 − x, InAsxP1 − x, and GaxIn1 − xPy, and deduce their bowing parameter energies which are used to calculate the form factors of the quaternary alloy of interest,

with

whereCGaInAs(Z), CGaInP(Z), CGaAsP(Z), andCInAsP(Z) are the Z-dependent bowing parameters of the associated ternary alloys.

Table 3 shows the bowing parameters of the considered ternary alloys GaxIn1 − xAs, GaAsxP1 − x, InAsxP1 − x, and GaxIn1 − xPy at different pressures and temperatures in comparison with the available experimental values.[26– 29]

The lattice constants of the quaternary GaxIn1 − xAsyP1 − y alloys are calculated by using Vegard’ s rule[30]

where aGaAs, aInAs, aGaP, and aInP are the Z-dependent lattice constants of the binary compounds GaAs, InAs, GaP, and InP, respectively.

The lattice matching of GaxIn1 − xAsyP1 − y alloy to GaAs substrate gives a relationship between the Ga and As concentrations (x and y)[14]

wher

with a’ s being the Z-dependent lattice constants of the binary compounds. The lattice constants of the binary compounds InAs, GaP, InP, and GaAs at different temperatures and pressures are displayed in Table 4.

| Table 1. Energy band gaps at different temperature and pressure for the parent binary compounds GaAs, InAs, InP, and GaP. |

| Table 2. The adjusted form factors of the binary materials GaAs, GaP, InP, and InAs for various temperatures and pressures. |

| Table 3. Bowing parameters of the parent ternary alloys at various temperatures and pressures. |

| Table 4. Lattice constants of the binary compounds at different temperature and pressure. |

The important parameter required to calculate the elastic constants of the GaxIn1 − xAsyP1 − y /GaAs quaternary system is its polarity, which is defined by Vogl[31] as

where

The cubic crystal has only three elastic constants C11, C12, and C44, so we calculate them by using the simplified forms[32, 35]

where d(x, Z) is the nearest-neighbor distance given by

The knowledge of the elastic constants C11, C12, and C44 at different pressures and temperatures allows us to calculate the corresponding Young’ s (Y0), shear (Cs), and bulk (B) moduli as follows:[34, 35]

The polarities of the quaternary alloys GaxIn1 − xAsyP1 − y lattice matching GaAs substrate are calculated with various compositions y at different temperatures and pressures. The elastic constants C11, C12, and C44 and the corresponding mechanical properties, such as bulk, shear, and Young’ s moduli, of the GaxIn1 − xAsyP1 − y/GaAs system are investigated. The variations of all of the properties of interest under the influence of temperature and pressure are investigated. A comparison between our calculated results and the available experiment and published data for the binary parent compounds shows that they have a very good agreement, while the calculated results for the quaternary alloys at various temperatures and pressures may be taken as a reference.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

|

| 21 |

|

| 22 |

|

| 23 |

|

| 24 |

|

| 25 |

|

| 26 |

|

| 27 |

|

| 28 |

|

| 29 |

|

| 30 |

|

| 31 |

|

| 32 |

|

| 33 |

|

| 34 |

|

| 35 |

|

| 36 |

|

| 37 |

|

| 38 |

|

| 39 |

|