†Corresponding author. E-mail: liujian@nimte.ac.cn

*Project supported by the National Natural Science Foundation of China (Grant No. 51371184) and the Outstanding Youth Fund of Zhejiang Province, China (Grant No. LR14E010001).

In the present work we reported the phase formation, microstructure, magnetocaloric effect and hydrogenation behavior of La-rich La1.7Fe11.6Si1.4 alloy. In this off-stoichiometric La(Fe,Si)13 alloy, the NaZn13-type La(Fe,Si)13 matrix phase shows faceted grains, with the Cr5B3-type La5Si3 used as the secondary phase distributed intergranularly. Such a peculiar morphology quickly forms upon one day annealing. In La1.7Fe11.6Si1.4 alloy, we have observed a significant field dependence of magnetostructural transition temperature (∼ 6.3 K/T), resulting in a large and table-like entropy change (Δ S ∼ 18 J/kg·K in 2 T) over a broad temperature range (∼ 10 K). Upon hydrogenation, the maximum value of Δ S keeps almost unchanged, while the Curie temperature increases up to 350 K. These results indicate that the investigated off-stoichiometric La(Fe,Si)13 alloy is a promising magnetic material for magnetic refrigerators.

Currently, magnetic materials showing a large magnetocaloric effect (MCE) have become a topic of growing interest, since the magnetic refrigeration technique based on the MCE is regarded as a promising alternative to the conventional vapor-cycle refrigeration.[1, 2] A large MCE is always observed in magnetostructural transition materials where the contribution of lattice entropy to structural transition is considerable.[3] Among such materials, La– Fe– Si compounds with NaZn13-type structure (the 1:13 phase) are one of the most promising magnetic refrigerants, as they hold several advantages towards magnetic cooling applications, such as low cost and nontoxic consisting elements, high magnetic moment and MCE, relatively low driven field and little hysteresis, and tunable Curie temperature (Tc) by elemental substitution or interstitial insertion.[4– 10] The solidified microstructure of as-cast stoichiometric La(Fe, Si)13 compounds usually consists of secondary phases including α -Fe and LaFeSi (the 1:1:1 phase). It is required at least one week homogenization around 1323 K to obtain the single 1:13 phase in La(Fe, Si)13 bulk alloys.[11] Due to this energy consuming and low efficient preparation, alternative techniques, such as melt spinning, [12] strip casting, [13] and powder metallurgical processing, [14, 15] have been developed to shorten annealing time. Till now, almost all previous studies concerned the synthesis methods, magnetic entropy change (Δ S), and adiabatic temperature change (Δ Tad) for La(Fe, Si)13-based stoichiometric compounds. Very recently, an off-stoichiometric composition LaFe8.8Si2.2 was reported, which has a single 1:13 phase directly formed in a solidification state, but shows a rather low value of Δ S (about 2 J/kg· K in 1.5 T).[16] In this paper, we present a new La-rich composition of La1.7Fe11.6Si1.4. Large Δ S of about 18 J/kg· K in 2 T in this alloy and its hydride was obtained. A peculiar microstructure and corresponding first-order magnetostructural transition, and hydrogenation behavior are investigated.

An ingot with the nominal composition of La1.7Fe11.6Si1.4 was prepared by induction melting in an argon atmosphere. As-cast alloys were annealed at 1323 K for different times from 1 to 7 days in a quartz ampoule filled with argon, and then quenched into ice water. Hydrogenation was performed in a furnace filled with 2 atm H2 atmosphere at 473 K for 5 hours to saturate H concentration.[17] The H concentration was determined by hot extraction method (ONH, TCH-600). The crystal structure was studied using a powder x-ray diffraction (XRD, Bruker D8, Cu-Kα radiation). The microstructure was observed by scanning electron microscope (SEM, FEI Quanta 250 FEG). The phase composition was analyzed by electron microprobe (EM, JXA-8100), which has a high accuracy about ± 0.1 wt.%. Magnetic measurements were carried out using a Quantum Design MPMS SQUID vibrating sample magnetometer.

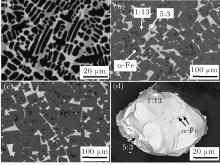

Apart from usually observed α -Fe and 1:1:1 phases in stoichiometric La(Fe, Si)13 compositions, an additional phase in La1.7Fe11.6Si1.4 was found by XRD presented in Fig. 1(a), which can be well indexed to be the La5Si3 phase (tetragonal, I4/mcm, a = 0.788 nm, c = 1.437 nm). Still, the α -Fe is the main phase in the as-cast sample. The phase constitution dramatically changed upon a short-time annealing for 1 day, as shown in the XRD pattern in Fig. 1(b). The phase constitution was almost unchanged upon annealing for 3 days as shown in the XRD pattern in Fig. 1(c). Full hydrogenation shifts all XRD peaks to lower angles excepted for the α -Fe phase, indicating that the values of lattice constant a increase from 1.142 nm to 1.155 nm for 1:13 phase, and for La5Si3 phase the values of lattice constant a and c increase from 0.788 nm to 0.798 nm and 1.437 nm to 1.483 nm respectively, as shown in Fig. 1(d). Figures 2(a)– 2(c) shows the microstructure of the specimens annealed at 1323 K for 0– 3 days. The as-cast sample contains the α -Fe (black phase), 1:1:1 phase (gray phase) and La5Si3 phase (white phase). From the SEM observation in Figs. 2(b) and 2(c), the 1:13 grains exhibiting a faceted morphology are surrounded by La5Si3. The volume fraction of the 1:13 phase nearly reaches 80%, whereas the La5Si3 phase was retained, but there observed little amount of α -Fe and no 1:1:1 phase. A prolonged annealing up to 7 days did not impact this microstructure very much (not shown here). According to the previously established La– Fe– Si ternary phase diagram, [18] the La5Si3 phase locates at the La rich boundary. The formation of this Si-rich and Fe-free La5Si3 phase is expected to result in the 1:13 matrix being depleted of Si, thus the concentration of Fe increases in the 1:13 matrix and the MCE is enhanced.[5] This assumption was confirmed by the result of electron microprobe, which suggests the real composition of the 1:13 matrix as La8.18Fe83.59Si8.24 ( = La1.16Fe11.83Si1.17). As the La(Fe, Si)13 compound with a lower Si content has a higher capability to absorb hydrogen due to a large weighted average Fe– Fe distance, [19] it seems reasonable that the present 1:13 hydride matrix contains high H content. The amount of H in this sample is measured to be 3100 ppm. This value is much higher than that in La1.0Fe11.8Si1.2(∼ 2320 ppm).[19] However, we are not able to exclude the H in the secondary phase La5Si3 without knowing its hydrogen absorption capability. Interestingly, hydrogen decrepitation process leads to single crystalline particles by almost keeping the initial shape and size of the non-hydrogenated 1:13 grains, as shown in Fig. 2(d). Also, some residual La5Si3 and α -Fe phases adhesive on fracture surfaces are visible. The form of single crystalline La– Fe– Si particles would seem more attractive for magnetic refrigerant applications.

| Fig. 2. SEM backscattered electron images of as-cast bulk La1.7Fe11.6Si1.4 (a), annealed for 1 day (b) and 3 day (c) at 1323 K. (d) Single crystalline hydride particle. |

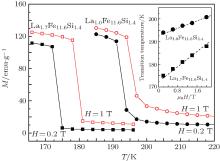

It has been known that in order to exploit the potential of Δ Tad in a finite field for first-order transition materials, a sharp magnetostructural transition is desirable, and more importantly the field dependence of transition temperature (dTc/dH) has to be optimized.[3, 20, 21] The optimal value of dTc/dH for Ni49.8Mn35In15.2 is 7.8 K/T, [3] and 6.5 K/T for La(Fe, Si)13system.[20] From the magnetization versus temperature at different fields (0.2 and 1 T) in Fig. 3, the value of dTc/dH for La1.7Fe11.6Si1.4 is calculated to be 6.3 K/T that is very close to the theoretical optimized one suggested by Sandeman.[20] This ideal case would give rise to the maximum Δ Tad of 13 K.[20] A large Δ Tad of 5.5 K in 2 T has been found by the direct experimental measurement for La1.7Fe11.6Si1.4 (not shown here), but still far from the theoretical value. This discrepancy implies that a higher driven field is required to reach the upper bound of cooling effect. Nevertheless, the large dTc/dH and steep transition in first order transitions are favorable for the table-like temperature dependence of MCE, as reported in antiperovskite Mn3GaC alloys.[22, 23] In comparison, stoichiometric composition La1.0Fe11.6Si1.4 shows a smaller value of dTc/dH about 3.6 K/T and slightly smeared magnetostructural transition at high fields.

Figure 4 shows the isotherms and related magnetic entropy change as a function of temperature and field for La1.7Fe11.6Si1.4 annealed for 3 days and its hydride La1.7Fe11.6Si1.4H2.9. For La1.7Fe11.6Si1.4, the magnetization curves at temperatures well above Tc (173 K) show very small low-field susceptibility due to a little amount of α -Fe phase. A sharp change in magnetization above Tc from 184 K to 175 K takes place at a critical field. Combined the well-defined onset field with the observed large magnetic hysteresis width (∼ 1 T), this compound undergoes a typical first-order magnetostructural transition.[24] The entropy change Δ S is calculated by using the Maxwell relation

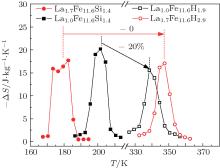

Last, we compare the influence of hydrogenation on the Tc and MCE between La1.7Fe11.6Si1.4 and La1.0Fe11.6Si1.4, as shown in Fig. 5. One aspect is that the decrease of the Δ S upon hydrogenation in La1.0Fe11.6Si1.4 is about 20% (the data taken from Ref. [15]), whereas it keeps constant in La-rich sample. On the other hand, the Tc of La1.7Fe11.6Si1.4 is lower than that of La1.0Fe11.6Si1.4, but hydrogen shifts Tc of La1.7Fe11.6Si1.4 to a higher value exceeding that in La1.0Fe11.6Si1.4. This phenomenon has been explained by the different space for H in the unit cell.[20] From this result, it can be concluded that the 1:13 matrix phase of La1.7Fe11.6Si1.4 should contain more H than the single 1:13 phase in La1.0Fe11.6Si1.4 (about 2041 ppm), although the La5Si3Hy phase also contributes H concentration to the sum H amount.

We have reported a new off-stoichiometric La1.7Fe11.6Si1.4. The dual-phase structure with 1:13 (80 vol.%) and La5Si3 phases can be obtained by only 1 day annealing. This novel composition exhibits table-like large entropy change. Hydrogenation results in the single crystalline 1:13 particles with size of 60– 80 μ m. The hydride particles contain high H concentration and high Tc, and exhibit large Δ S of 14 J/kg· K in 1 T accompanying with small hysteresis losses. These features suggest that the present La-rich alloy is a highly suitable refrigerant candidate for magnetic refrigerators.

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

|

| 21 |

|

| 22 |

|

| 23 |

|

| 24 |

|

| 25 |

|

| 26 |

|

| 27 |

|